Grease Gun – Why Is It Important in Machinery?

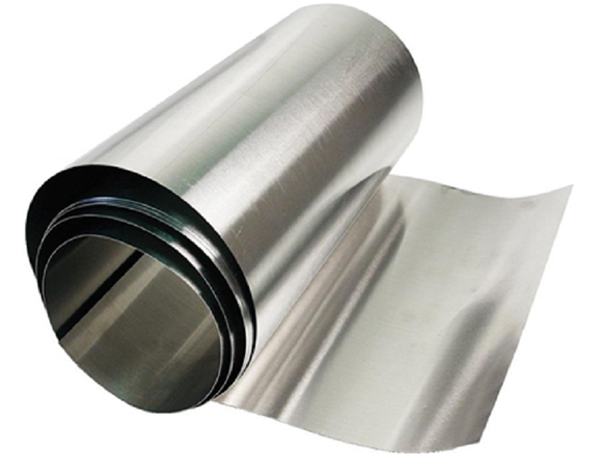

Stainless steel is not the only material that is used in preparing shims. Though there are many other materials, steel is highly preferable for many reasons. Materials like PTFE, brass; copper and even paper is used for making shims. But stainless steel happens to be one of the most preferable materials because of its durability and better life. Shins are thin strips made of the mentioned materials which are used in aligning parts of the machines. The material for the shin is chosen depending on the type of project. Stainless steel happens to be favorable for most type of projects. เครื่องมือตั้งศูญย์เพลา

Stainless steel as a material for shim

A special steel alloy containing minimum 10.5% of chromium is called stainless steel. Depending on the microstructure, stainless steel has 5 different categories. This material is not only great for shims but also for other purposes.

Less wear and tear

Wearing and tearing is very common but also problematic for any machinery. To lessen the amount of wear and tear, it is necessary to choose right products and materials in order to have the machinery work properly for long. When it comes to stainless steel, there are a few things to talk about. Iron reacts with oxygen which causes rust, hence wear and tear. But the alloying elements of stainless steel create a stable yet thin layer when it comes into contact with water and air.

As this happens, this layer becomes the protective layer against rust which causes even more corrosion. This metal is also more durable than many other materials used for shims. While brass is softer and more prone to dent and scratches, it will also get tarnished as it comes in contact with water. But stainless steel is capable of maintaining an aesthetic appeal for longer.

ความคิดเห็น

แสดงความคิดเห็น